Staining tight-grained woods like Hard Maple is a problem for finishers. For amateurs the best advice is to avoid staining hard Maple, Birch, and Cherry. Understand that staining--without blotches--is difficult. Not impossible, just difficult.

Tips For A Darker Stain On Hard Maple

Now, if you still want to get a darker finish on your Maple Cabinet Doors, here are some tips.

- Tip Number 1, Do not stain! If you want a darker finish on Maple, use a Dye

- Tip Number 2, Always start staining on the backs, so if you hate the stain experiment, you will not see it every day.

When staining soft maple Kitchen doors and drawers from a millworks shop the painter applied a special walnut stain directly to the raw wood. The stain did not take well on wood milled with the grain, and on cross cuts the stain soaked into the wood giving a dark black color. How do we prevent the cross cut problem and promote a uniform acceptance of the stain.

And here are several replies...

Hey Robert. Uneven staining can be a real pain. There are a few things you can do to even things out in the future. First, you should sand the end-grain to one or two grits higher than the rest of the piece. So if the piece is sanded to 180, you should sand the endgrain to 220 or 320. The finer sanding will help prohibit stain absorption. Another technique is to apply a glue size to the endgrain. Make a 10:1 mixture of water and yellow or white glue. Brush this solution onto the endgrain and give it several hours to dry. Once dry, sand lightly and proceed with staining. The embedded glue will prevent excessive stain absorption. You can also use a light coat of shellac or any sealer to the same end. And remember to always test on scrap or inconspicuous areas to ensure you get the look you are after. Hope these ideas help.

Because maple has such tight grain, pigment type stains don't soak into the wood, except where there is a spot with more open grain, as you found out. Try using dyes, such as TransTint or Transfast. There are other brands as well often marketed as aniline dyes. You should always make a habit of trying finishes on scrap left over from your project before tackling your project.

If you use oil based stains, you cant beat MinWax Wood Conditioner on Maple. It totally eliminates the blotchyness and makes the color very even.

Here are links to several good Youtube Videos...

- Staining Maple Doors

- Understanding and using Dyes

- Coloring/Staining Blotchy Woods

- How To Finish Maple Wood

- The Do's and Don't of Staining Maple Cabinet Doors

How To Stain Hard Maple

Here is an internet post about problems staining maple and 15 suggestions from readers...

I really need some advice on staining maple. I just finished an entertainment center built out of maple and birch ply. I only discovered the difficulties of staining these woods after the fact. I want a dark color that wont appear black when I finish. Just a standard darker color like cherry or something similar. Please help! Thanks, Jonathan Dean

15 replies so far

#1 posted 10-07-2010 04:03 AM

It almost sounds like you have discovered the difficulties be staining it already. I would practice with some stains on scrap pieces the check for the results you want. Also, you might want to consider giving it a coat of Zinsser sanding sealer and lightly sanding or rubbing it with steel wool it before staining to help prevent blotchiness. But always practice first on scrap. You might want to try a couple of colors of gel stain to see if you like the way it applies. -SST

#2 posted 10-07-2010 04:15 AM

Maple is hard and dense, so the relatively large pigment particles can not penetrate the wood very well. They even highlight the sanding scratches.

Try some dyes instead, like TransTint, a concentrated dye that you mix with water.

#3 posted 10-07-2010 04:22 AM

Why would you use maple if you want a dark finished product? I dont understand. If you want figure, thats OK. But you will have to use a sealer if you want some sort of uniform finish on maple. Dye is a better bet, but only if you want pop.

#4 posted 10-07-2010 05:04 PM

Both your woods are notorious for blotching.

- Minwax makes a product for this: Minwax Pre-Stain wood conditioner.

- Application tool: cloth or brush

- Dry time: 15 minutes

- Stain Application: after 15 minutes, but no more than 2 hours

- Cleanup: mineral spirits or paint thinner, following manufacturers safety instructions

- Coverage: 125 sq. ft. per quart

- Coats: normally 1, but additional coats may be applied on highly absorbent woods

- Recommended uses: any soft or porous woods. Common examples include pine, fir and spruce or maple, alder and aspen (porous)

- I have used it but not with astonishing success. It was an improvement over not using it.

#5 posted 10-07-2010 05:57 PM

I have had success using a dye as mentioned above and then put a spit coat of shellac over that, then when dry a light sanding with 0000 steel wool or a buffing pad (gray). Then apply a coat of Gel stain to get the color and tone you want. Hope this helps.

Best Answer #6 posted 10-07-2010 06:41 PM

Two parts to this post. First; Preventing this in the future. The technique I use for getting dark stains in Maple is based on instructions graciously posted by M. Spagnuolo on his site (thewoodwhisperer.com) and the technicial musings at woodweb. It is not perfect, but It will get closer to a piano finish given time.

- Moisten maple with damp cloth, you are only looking to raise the grain not force enough water in to warp the wood

- Sand to 120, 180, 220, with preferred method, you are looking to prep an even and smooth surface, knocking down all the raised grain

- Coat with dewaxed 1lb (Zinsser Sanding Sealer cut 50% with Denatured Alcohol) thinly

- Mix Analine--TransTint dye with water, apply by rag with a light hand. You have some protection from oversaturation from the shellac sanding sealer, but even with dye you can cause slight blotching with maple/birch ply. You will not get the color you want in the first coat, for darker applications it is more like five to ten.

- Once dry at the right hue you will want to apply a tinted dewaxed shellac (2lb) using a slightly more warm shade than used in the water based dye. Analine dyes are remarkably flat, the shellac overcoat is intended to warm the color. Again a light hand since the dyes will react with the alcohol, not enough force to move them around

- Top coat with your preferred finish. Oil and Urethene will provide a very durable finish, poly will also work if you want a bulletproof finish.

Second, dealing with the situation of a blotchy entertainment center sitting in your shop

If you have time you can strip the surface using a dichloromethane based stain/varnish stripper. Please note, it is very caustic, will cause a first degree chemical burn if applied to skin. Wear gloves, wear goggles, work with plenty of fresh air. For the solid wood parts an alternative is to sand, but on ply parts you will have to be careful. Once you have removed the stain you can go ahead with a coloring/finishing routine

If you are out of time on the project then you will have to use a tinted shellac/glaze method that will obscure the grain. You are looking to create a smooth finish by applying full strength tinted shellac and glaze coat. Stick with dewaxed to avoid topcoat problems, and apply enough coats to hide the blotchiness.

Best of luck

#7 posted 10-07-2010 07:17 PM

Thank you everyone! Atomjack, I really did not plan on staining this piece dark to start with. I thought about some sort of clear coat but my wife changed her mind and thought it would better match our den with a darker color. The advice has been very helpful. I will try a few such as the dyes and gel stain with of course the prestain before going through with anything.

#8 posted 10-08-2010 12:50 AM

I use dye stains from Mohawk or Behlen or M L Campbell has stains that will wipe and or spray well. I have found these methods produce the best clarity with no blotching. No mixing or sealer coats before staining. Good for toning uneven color also. The reason to choose maple and stain it dark is that it is a wood that is relatively cheap with nice tight grain features that can be made to look like a variety of woods.

More About Applying Minwax Pre-Stain Wood Conditioner

#9 posted 10-08-2010 03:11 AM

The only thing I would add to the above is about the min-wax stain conditioner.

- I have had much better luck letting it dry overnight.

- Then wipe with a rag damp with mineral spirits.

- If an area soaks in/dries much more quickly than the surrounding area, coat that area again and repeat the overnight dry.

- The soak-in area is where you will have a darker blotch in your stain. When it is even, then lightly scuff sand before applying your stain.

- If the stain will not penetrate, use a higher grit sandpaper with a block and with the grain.

- The more porous wood should still stay sealed unless you over-sand.

- The spirits wipe also will work with the Zinsser, (overnight dry not needed) altho I have not tried the cutting the 2# mix to 1#, which I will in the future. Thank you Nathan Allen for the tip.

#10 posted 10-08-2010 05:31 PM

Gofor, exactly, technically we should be using flakes, but having dewaxed #2 that can be cut to #1 and sit on the shelf about a year is too convienent.

And thank you for the tip on Minwax, I have avoided staining maple because I could never get the samples right even with conditioner, but mineral spirits should help identify those spots.

#11 posted 10-15-2010 09:03 PM

I am sure by now you have decided on a process, but I thought I would throw this out. I use Seal Coat cut 50/50 with alcohol as NathanAllen described. I, however, favor gel stains for these types of hard to stain woods especially if trying for a dark color. I have had really good success with them. The General Finish products seem to work the best for me but I have used other brands with good results too. Charles Neil also sells a water based product that does a great job as a seal coat. Using it or using the shellac method described above I have been able to get excellent looking results using pine and popular in addition to maple.

#12 posted 10-19-2010 02:44 AM

Ron thanks for the advice! Do you have a recommendation for which general finish gel stain to use. I was thinking the antique walnut but I want a dark color but not so dark it looks black! I want to see the grain patterns and bring out my work. Let me know if you have a suggestion. Thanks!

#13 posted 10-20-2010 03:26 AM

I did a recent project out of maple ply and had no problem with any blotching on the plywood (the solid hard maple is another story for a different time). I used minwax pre stain conditioner with minwax red mahogany oil based stain. It is my only project posted on here but you cant really see the plywood. All you can see is the solid drawer fronts and they turned out horribly blotchy but it was because of my own error. I had no blotching what so ever on the plywood using this method though and the grain pattern shows pretty well also.

#14 posted 10-20-2010 05:29 PM

For the table I think I used GF Candlelight but my wife wanted it still darker so I used another shellac wash coat followed with a final coat of GF Java which is really dark which is why I used the wash coat in between. The table is on my project page if you want to have a look.

#15 posted 10-20-2010 05:36 PM

Just my two cents. I vote for Zinsser over Minwax.

Uneven Walnut Stain On Maple

Here is a post about Uneven Stain Absorption and a solution...

Added on April 17, 2007

This week the question comes from Robert. He writes:

When staining soft maple Kitchen doors and drawers from a millworks shop the painter applied a special walnut stain directly to the raw wood. The stain did not take well on wood milled with the grain, and on cross cuts the stain soaked into the wood giving a dark black color. How do we prevent the cross cut problem and promote a uniform acceptance of the stain.

And here was my reply:

Hey Robert. Uneven staining can be a real pain. There are a few things you can do to even things out in the future. First, you should sand the end-grain to one or two grits higher than the rest of the piece. So if the piece is sanded to 180, you should sand the endgrain to 220 or 320. The finer sanding will help prohibit stain absorption. Another technique is to apply a glue size to the endgrain. Make a 10:1 mixture of water and yellow or white glue. Brush this solution onto the endgrain and give it several hours to dry. Once dry, sand lightly and proceed with staining. The embedded glue will prevent excessive stain absorption. You can also use a light coat of shellac or any sealer to the same end. And remember to always test on scrap or inconspicuous areas to ensure you get the look you are after. Hope these ideas help.

A good article on how to Avoid Color Mistakes and Learn How to Fix a Blotchy Stain...

http://www.finewoodworking.com/how-to/article/avoid-color-mistakes-and-learn-how-to-fix-a-blotchy-stain.aspx

This article contains a great video on wood finishing tips

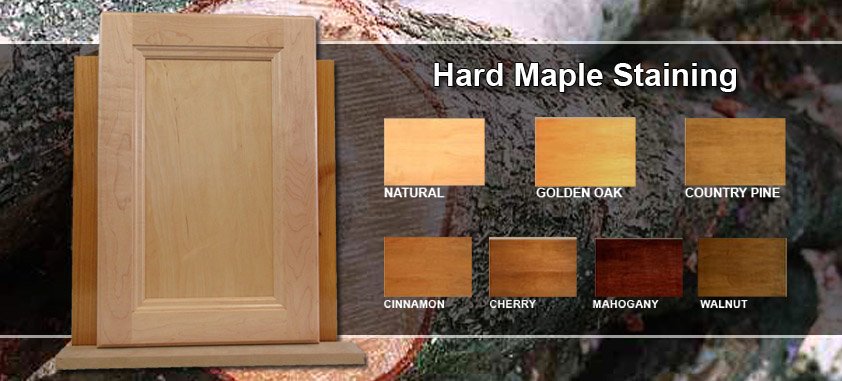

Hard Maple Stain Color Options

- Natural

- Golden Oak

- Country Pine

- Cinnamon

- Traditional Cherry

- Traditional Mahogany

- American Walnut