Choosing Kitchen Cabinet Doors

Are you wondering where to buy kitchen cabinet doors and how to choose the right type for your kitchen? Keep reading to learn about how kitchen cabinet doors are constructed, how to choose your finish, and how to buy kitchen cabinet doors online that are ideal for your home.

Kitchen cabinet doors live in a stressful environment. While other doors and wood products in your home are able to get by without having to adjust to big fluctuations in humidity and temperature, they aren’t exposed to the same level of cleaning and moisture as the wood in your kitchen and bathrooms. Because they’re located near the stove, the sink, and the dishwasher, kitchen cabinet doors experience larger humidity and heat fluctuations throughout the day and over the course of the year. The humidity issues faced in bathrooms are often even more serious because of the repeated exposure to large amounts of steam. In order to stand up to these fluctuations, kitchen cabinet doors must be made and finished in a way that accounts for this exposure. If you don’t plan well, be prepared to learn now to replace kitchen cabinet doors regularly.

How to Buy Kitchen Cabinet Doors That Stand Up to the Kitchen Environment

Because kitchen cabinet doors are exposed to a harsher environment than doors in other areas of the home, they require additional design consideration. It’s important that you are choosing kitchen cabinet doors that allow for more wood movement due to greater moisture gain and loss. This wood movement is the reason the panels in kitchen cabinet doors are trimmed to be slightly shorter and narrower than the space available within the door's frame. This allows the panel to expand or contract as humidity changes, without cracking the frame joints.

As wood reacts to changes in humidity, it expands and contracts. A well-designed kitchen cabinet door allows space for the panel to react to environmental changes. Below, you’ll see an illustration of how wood expands. As humidity increases, the moisture content in wood also increases. This causes the wood to expand slightly. This expansion in width across the grain, shown below on the left, is usually about 1/16 inches per foot of width. Expansion in height is with the grain, shown below on the right. This expansion is typically much less when compared to the width expansion, averaging about 1/64 inches per foot. The calculation of space needed to allow for humidity change varies with wood type, and with individual door width. Trimming the size of the door's panel to allow for humidity expansion is critical to ensuring that a door used in the kitchen will be reliable.

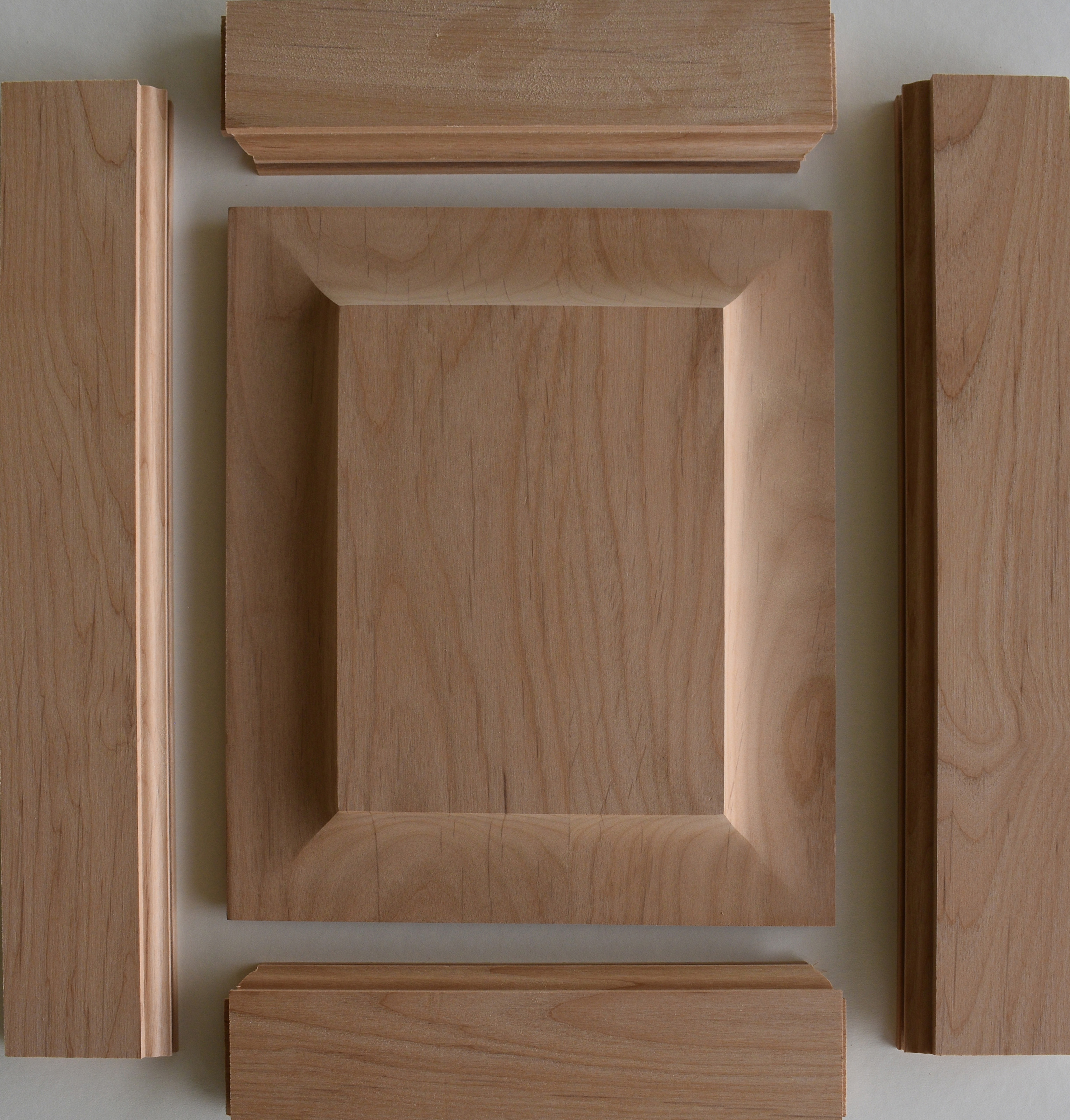

How 5-Piece Cabinet Doors Assembly Accounts for Expansion

The frame of a cabinet door consists of the vertical stiles, and the horizontal rails. The panel is in the center. which is captured within a groove machined into the stiles and rails. During assembly, the panel is inserted into the stile & rail grooves and the frame is glued and pressed to close the joints, which are then pinned in place. Because wood reacts to moisture changes by expanding or contracting, the panel is not glued inside the frame. The panel, being larger than the frame pieces, will react to moisture changes by expanding or contracting more than the frame. For this reason, the panel is not glued and is instead allowed to float within the frame's grooves. The door's design compensates for the expected humidity fluctuations by sizing the panel about 1/8th inch smaller than the groove depth. This method ensures that increases in humidity, which will cause the panel to widen, will not push the frame joints apart.

In the photo below, a Shaker Cabinet Door stile and rail are ready to be glued and pressed together. This Shaker Door stile is machined with a continuous groove running along its length. The Shaker rail also has the continuous groove but has the mirror-image of the groove machined into the ends. This joining method is known as mortise and tenon and is used on all cope and stick, and mitered doors. During assembly, the tenon on the end of the rail is glued into the mortise inside of the stile.

This photo below shows the cope and stick joint being closed. The rail’s tenon is pushed into the mortise in the stile. The stiles and rails are glued and pressed together, forming the frame of the cabinet door. The panel is inserted into the remaining grooves of the stiles and rails during the assembly process.

Mitered doors fit together similarly, using the mortise and tenon joint technique. Machining has evolved for mitered doors over the past few years from simple butt-jointed frames that were attached with dowels or biscuits. Today, modern computerized machinery promises a level of accuracy impossible by other methods.

Kitchen Cabinet Door Components

This Cope and Stick Cabinet Door shown above is ready to be assembled. Glue will be applied where the stiles and rails join. As previously mentioned, the floating panel is not glued because a glued panel cannot expand and will actually cause the frame to break or push apart. The panel is inserted into the grooves, and the frame is squeezed closed with a hydraulic press. The same gluing process is used to close the frame on the Mitered Cabinet Door below. Notice the mortise and tenon is machined into the mitered door's stiles and rails.

To achieve superior finishing results, exceptional sanding is an absolute must. Modern sanding machines are necessary to achieve the surface required for a truly outstanding level of finish. We utilize five of the latest wide-belt sanders in our operation.

How to Replace Kitchen Cabinet Doors with the Right Product

If the temperature and humidity levels were constant and never changed, cabinet doors would last a century. However, temperature and humidity do fluctuate, so understanding how to buy kitchen cabinet doors that can handle those changes is essential. Because humidity is constantly changing, the wood in the door is constantly changing dimensions too. That's why we allow the panels to float—this way, the door will be able to survive in an environment like your kitchen. The floating panel, which is not glued to the frame, is able to change in size without even being noticed.

But, what about the frame? The stiles and rails will also change, very slightly, in both width and length. However, the change is slight enough that it will not create a structural issue, and with the consistent climate control found in most homes this slight movement around 1/16” will not be noticed.

Choosing Kitchen Cabinet Doors With the Right Finish

Proper finishing of kitchen cabinet doors provides the final level of protection. While an unfinished door offers no barrier to moisture, finishing adds an extra barrier, protecting the wood from moisture and excess wear and tear. However, there is a wide range of protection offered by different finishes. Here is a breakdown of protection methods from worst to best.

-

Stains or water-based paints: Usually short-lasting and least likely to slow moisture absorption

-

Conventional lacquers and oil-based paints: Offer mid-range levels of protection

-

Conversion varnish: The most difficult to apply and the most expensive, but offers the highest level of protection

Conversion varnish is a two-part, post-catalyzed lacquer, with a hardener that is mixed with the product before it is applied. Conversion varnish is typically professionally applied, as it requires a specialized process while drying. This high-tech product is used in modern manufacturing for painting plastics, metal, and wood because it has proven to produce a smooth, hard, and durable finish.

If you are considering painting your cabinet doors, it’s important to note that it is nearly impossible to avoid slight cracking of dry paint when the wood under the paint moves. While the wood remains flexible and reacts to moisture changes, paint hardens and can't stretch with the wood. Painted wood cabinet doors installed outdoors, or in a space that is not temperature controlled, are likely to show paint cracks at the joints. If these same doors are installed in a home with normal heating and cooling, paint cracking may still occur, but less.

The slight changes in the width of the stiles and rails are normal, minimal, and expected as humidity changes. The integrity of the door is not diminished because the wood is somewhat elastic. The paint, however, becomes rigid when it dries and is unable to expand or contract with the wood. The solution is to minimize the moisture changes within the wood through normal levels of home climate control. Although no paint can guarantee it won’t crack when wood expands, conversion varnish comes the closest. Conversion varnish remains more flexible than traditional paint so cracking is less likely, but can occur over time. This is considered normal wear and tear.

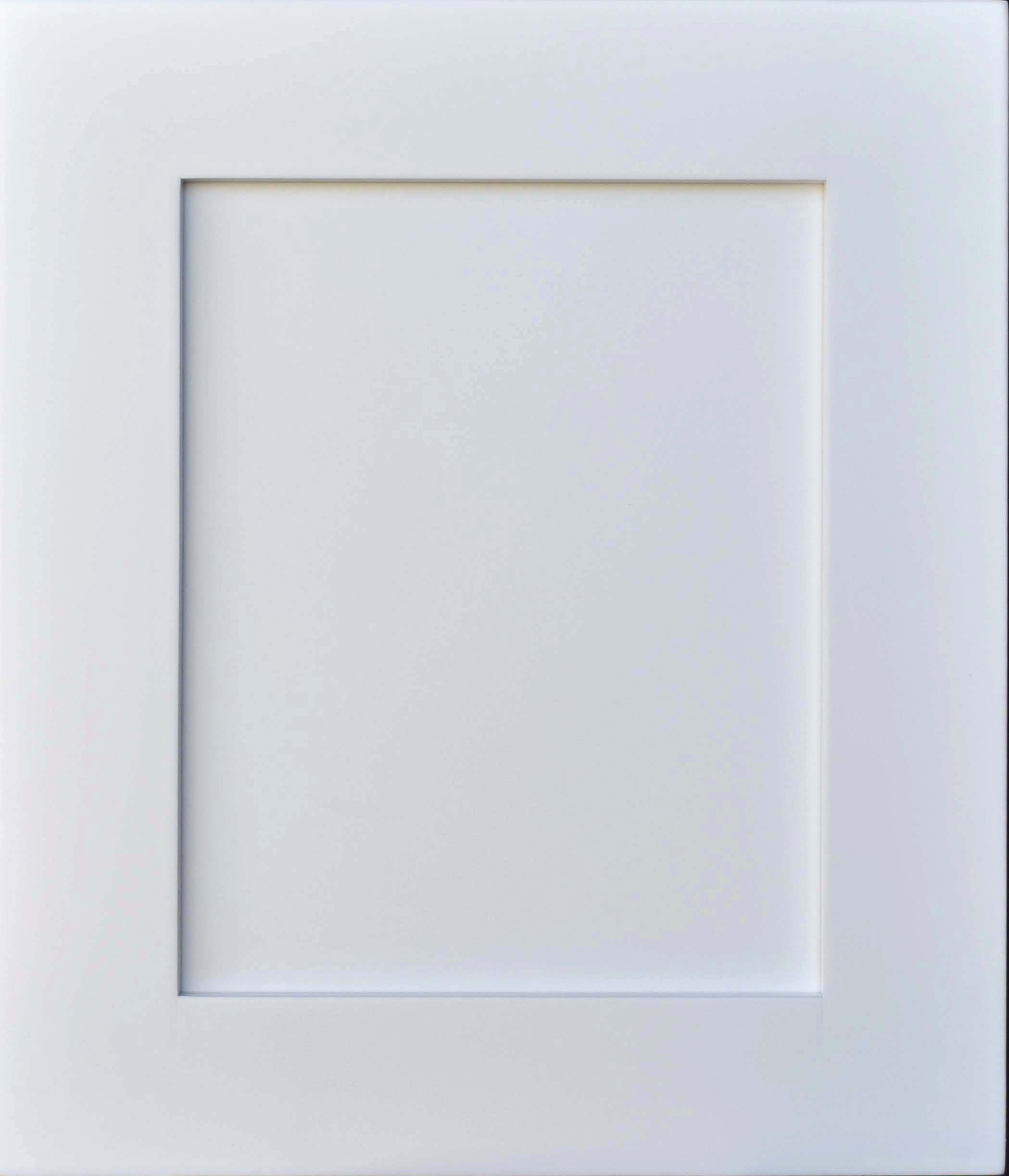

Shaker Paint-Grade Painted High-Reflective White with Conversion Varnish

How to Replace Kitchen Cabinet Doors With the Ideal Design

Kitchen cabinet doors aren’t just one element in the room—they’re an essential element. In many kitchens, the cabinets dictate the look and feel of the whole space, and no element of the cabinet is more visible than the doors. That’s why you can transform the aesthetic in almost any kitchen simply by hanging up replacement kitchen cabinet doors. The question is, what kind of doors will you choose?

When it comes to choosing kitchen cabinet doors for your home, make things easier on yourself by ordering custom-built kitchen cabinet doors for sale. Rather than trying to find something you like in a big-box store, custom-built replacement kitchen cabinet doors can be made in a style you love to fit your cabinets perfectly. Cabinetdoors.com has an extensive selection of cabinet doors to choose from, which can all be custom-sized to meet your needs. From there, what should you look for when choosing kitchen cabinet doors?

First look at the door design, including all the lines, embellishments, and details built into the structure of the door. Some cabinet doors are modern and minimal, others are classic and cozy, and others have bold, attention-grabbing elements. Find a look you like, then decide whether you want to finish the doors with paint, stain, or a natural wood with a clear coat. Think about the hardware you will use on the kitchen cabinet doors too, as it can transform the look of your doors.

You can also consider Glass-Ready Kitchen Cabinet Doors to incorporate into your kitchen. Glass doors have been growing in popularity for years and today are being incorporated into high-end house designs at an increasing rate. Every cabinet door style at Cabinetdoors.com is available with the frame-back modified to accept glass panels. Pictured above is the Wilmington Mitered Glass Door. Like every glass-ready door we offer, it will be delivered with the back milled and ready for user-supplied glass to be installed. In order to install your glass, simply place the glass into the inset area in the back of the frame and apply a fine bead of silicone caulk. This will securely hold the glass and eliminate rattle.

No matter what design and style you ultimately choose, there are plenty of options to consider at every step in the selection process. Even better, with custom doors, you can mix and match the individual elements to achieve literally any look you desire. Take some time to consider all your choices. Most importantly, work with a supplier of kitchen cabinet doors that gives you plenty of choices to consider.

Where to Buy Kitchen Cabinet Doors

If you’re wondering where and how to buy kitchen cabinet doors online that can be custom-sized for your space, Cabinetdoors.com has you covered. We are the leading online source for replacement kitchen cabinet doors. Do you need quality doors that fit your existing cabinets? Turn to the source used by designers and home contractors across the nation and order the doors you need. We have a huge selection of styles and designs that can be customized to meet your needs. When you’re ready to buy kitchen cabinet doors online, we make the process easy, affordable, and accessible.

When you buy kitchen cabinet doors online from Cabinetdoors.com, you’re ordering factory-direct. That means you get the factory-direct price, without the retail markup. You’ll not only be getting custom, high-quality cabinet doors made to your exact specifications, but you’ll also be getting them at prices 30-50% lower than what you’d find at big box stores. Wondering how to buy kitchen cabinet doors you love at a great price? Cabinetdoors.com is your solution.

At Cabinetdoors.com, we know that choosing kitchen cabinet doors is a big decision. Deciding where to buy kitchen cabinet doors doesn’t have to be. To help you with any lingering questions, we have provided answers to some of the most common questions and confusions we hear about kitchen cabinet doors in our FAQ Guide about Kitchen Cabinet Doors. If you don’t find the answers you need there, feel free to contact us through the website or at sales@cabinetdoors.com with any questions about how to buy kitchen cabinet doors for your space. We’re confident we can help you decide how to replace kitchen cabinet doors with doors you’ll love for years to come.